Abattoir shall have an adequate separation between clean and unclean section. The sections should be arranged in such a way that from the introduction of a live animal into the abattoir up to the emergence of meat and offal classed as fit for consumption, there shall be a continuous process, without any possibility of reversal, inter-section or over lapping between the live animals and meat, and between meat and by-products or waste.

Main Components of An Abattoir :

The modern abattoir layout is as follows keeping in view humane method of slaughter and hygienic, wholesome and safe meat production.

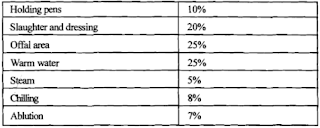

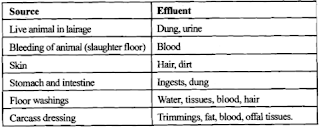

(i) Stockyard: It is meant for collection and marketing of livestock in a large number. It should be roofed to protect animals and staff. There should be facility to unload the stock particularly from lorries. All the stock must be handled gently and quietly. As per nature animals prefer walking up slopes rather than down steep gradients and it should be kept in mind while designing stock yard. Stock yard should have enough open area for vehicle turn and usually should be located opposite to the side from where processed product I meat is despatched. Here the animals are examined by veterinarian before sending to lairage. Unless all animals are arriving on hoof, proper ramps for direct unloading of animals from trucks or railway wagons should be provided and the ramps should directly Plant Layout, Design and Construction of An Abattoir lead to ante-mortem area with office room for veterinary inspector. This area should have water and feeding facilities. There should be separate isolation pens with watering and feeding arrangements for (i) animals suspected to be suffering from contagious and infections diseases and (ii) fractious animals in order to segregate them from the remaining animals. Suspected animals are sent to isolation pen directly from stockyard. This area also should have water and feeding facilities.

(ii)lairage: It is meant to keep two to three days stock for slaughter. After passing through reception area the animals reach to the lairage where these are rested before slaughter. The rest is being given to restore their normal physiological condition. Usually animals travel long distances to reach abattoir and if not rested properly the quality of meat is adversely affected. The lairage should be equipped with all facilities to feel animal comfortable and for this it should be protected from heat, cold and rain. It should be spacious enough (2.8m^2f of each large animal and 1.6m2f or small animals) to accommodate the large animals that will be slaughtered in 2 days and small animals for one day slaughter. Lairage should be provided with abundant water and feed. This section should be so constructed that the animals can be kept separately depending upon their type and class. The lairage should have adequate facilities for ante-mortem inspection. There should also be the separate isolation pens for suspected and fractious animals as in case of stockyard. Where separate lairages are to be provided for livestock meant for different method of slaughter like Halal, Jhatka or Jewish slaughter, complete visual separation shall be effected and entrances shall be kept as far apart as possible.

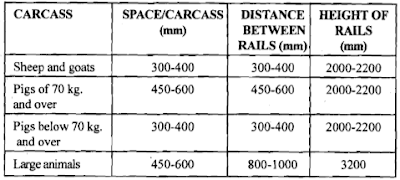

(iii) Slaughter househall: From lairage, animals are transferred to slaughter hall, which is usually situated at a distance of 10 meter from lairage. Wherever required, separate provisions for slaughtering, dressing and processing of small animals and also for slaughtering of animals under different slaughter method should be made in an abattoir. Exits to such sections should be kept as far apart as possible. It has several sections:

a) Drive/races: Firstly, the animals reach to holding pen and then they are driven to stunning pen through drive/races. Drive is usually a curved path with single file accommodation and stop gate. Animals are continuously being guided by a person to stunning pen.

b) Stunning pen: It is the area where animals are made unconscious before killing. Its design depends on type of stunning procedure to be followed.

c) Bleeding area: Immediately after stunning, the animal has to be bled to death. This area should possess a good gradient for collection of blood. This area should be so located that the blood shall not be splashed on other animals being slaughtered or on the carcass being skinned. Blood drain and collection should be immediate and proper. The minimum diameter of the blood drain shall be 150 mm and-shall be sloped not less than 170 mm per meter to the discharge point. The bleeding trough for large animals shall be at least 1.5 m wide and 1.1-1.2 m for small animals and swine. It should be enclosed on both sides and shall have a smooth impervious surface such as stainless steel. For small stock bleeding area,galvanized steel or aluminium grating shall be provided.For large animals,the overhead bleeding rail should be there. A hand wash basin and knife sterilizer should be provided in this area for the sticker to sterilize knife.

d) Carcass dressing area: In this area a number of operations are carried out such as removal of hide and skin, head removal, evisceration, splitting, trimming and final wash etc. Dressing of carcass should not be done on floor. Adequate means for immediate disposal of hides or skins should be provided. The hides and skins, should never be spread on slaughter floor for inspection. There should be provisions for immediate disposal of legs, horns, hooves etc. Floor wash point, adequate number of hand wash basins with sterilizers and hot and cold water outlets should be provided in this area Sufficient space should be provided for the deborning, removal and thorough washing of heads. If pigs are slaughtered, then the swine scalding tank and dehairing equipment should be separated from the rest of the dressing area. The scalding tank should be equipped with overflow facilities. For a slaughter house with higher slaughter rate (25 or more cattle/hr or 150 or more swine/hr), a moving top evisceration table should be provided with cold water sprays to remove blood and extraneous material and be synchronized with the eviscerating rail. This also should be installed together with the facilities for the systematic removal of all organs and parts. There should be facilities such as racks or trays or equivalent means to accommodate and maintain the identity of organs and parts detained for veterinary diagnosis.

e) Inspection area: Before evisceration the carcass has to be examined carefully for any pathological lesions. Once the carcass is ready for sending to the next section all its visceral organ and the whole eviscerated carcass are reexamined carefully. Then, it is decided whether the carcass has to be sent to chilling section or condemned meat room or detention room, Adequate facilities and space should be there for inspection of the viscera of various types of animals slaughtered. Hand wading, tool sterilization, floor washing and facilities for separation and disposal of condemned material should be provided in this area. Adequate arrangements for identification, inspection and correlation of carcass, viscera and head should be made there.

f) Carcass washing area: A separately drained area or an area of sufficient size slopped to a floor drain should be provided for washing of the approved carcasses with a jet of water. This area should be well curbed

(iv) Cold storage: If the meat is to be consumed immediately after dressing i.e., in hot condition, the carcass has to be sent immediately for sale and cooking. Otherwise in all other cases carcass should be chilled soon after the postmortem inspection. As per EEC regulation, chilling temperature for carcass should not exceed 70°C while for offal it should be below 40°C. Chilling is practiced to set up the meat firmly and check any microbial growth. The carcass is held in chilling room for three days and this process is also known as ageing. All blast freezers and holding freezers should be capable of maintaining temperature of - 25°C or lower and -18°C or lower respectively. There should be provision for measuring relative humidity and temperature. Chill doors should be sliding or single or double-hinged. Internal finishing shall be durable, impervious and with good insulation and floor drainage. All freezers should be equipped with thermographs an facilities for securing with locks.An area in the cooler shall be provided for the chilling and storage of detained carcasses and parts, This area Should be segregated from the remainder of the cooler and shall be equipped with seal and lock.

(v) Cutting and deboning room: Once the carcass is firmly set in chilling room, deboning (separation of meat from bone) becomes easier and cut into pieces. The operation is performed in controlled temperature (10-12°C) area by skilled and efficient worker. An adequate number of knife sanitizers should be provided at strategic locations and the area should have illumination of 220 lux.

(vi) Packaging and despatch section: Adjacent to cutting and deboning room there is packaging room where the meat chunks are packaged and after freezing they are kept under frozen condition (-40°C) before despatch. The despatch area should be adequate in space and shall allow for the orderly and efficient loading of meat into transport vehicle. At the time of loading, docking system is practiced whereby there is no air movement into the despatch area or vehicle.

(vii) Condemned meat room: It is directly connected with inspection area. An adequate space, refrigeration and drainage along with supply of durable and lockable container and weighing facilities are essential in order to arrange for sorting and holding of materials unfit for human consumption prior to despatch. This room should be provided with only one door located outside the building and should be provided with lock. At the planning stage of plant due attention should be given to condemned meat room.

(viii)Detained meat room: Suitable and sufficient facilities should be provided for the isolation of the meat requiring further examinaton as sometime the inspector/veterinarian may be neither in a position to discard the carcass nor to pass it to chilling section. In such cases a detailed report from quality control laboratory and viscera examination section is needed. Detained meat room should be located adjacent to the main slaughter hall inspection point and also to be connected with condemned meat room as well as chilling section and after clearance of pending decision, carcass is accordingly sent. If carcass has to detain for longer time there must be facility for chilling. Enclosure and lock should be provided

(xi) Quality control laboratory: This is meant for detailed examination of specimen from carcass and their respective viscera. Microbiological test, trichinoscopic test etc are conducted here. This area should be well equipped for detail examination of the carcass and the organs because the final decision of acceptance or rejection of the meat and the offals depends on the report of quality control laboratory. This area should be directly connected with the slaughter hall.

Accessories Sections of An Abattoir

Besides these main components of an abattoir, plant should have following accessories sections:

Blood collection: It is underground to bleeding area and may be divided into two-edible blood collection section and inedible one. Blood has got nutritional as well as commercial importance and it cannot be allowed in waste as in traditional slaughter system.

Hide and skin store: Along with other by products, hide and skin need to be stored before despatch Their safe storage and primary processing needs a separate section.

Gut and tripe room: A separate room and hanging space should be provided for emptying and cleaning of stomach and intestine and this room should have a separate exit. In this area, there may also be a provision for the preparation of casing, tripe and edible fat.

Red offal room: Many of visceral organs have commercial as well as food value. Among these liver, lungs, heart, kidney etc. are the organs which should be trimmed and then placed in a chill or freezing room depending on ultimate system of disposal. The temperature of offal room particularly those to be used as food should not exceed 3°C. This room should be divided into edible and inedible sections for further processing. These sections should be preferably separated from the slaughter floor except for one or two connecting doorways with self closing doors.

Rendering plant: This section deals with extraction of fat from carcass parts, condemned carcass/diseased one by applying high temperature processing. The materials left after fat extraction may be used for animal feed-fertilizer. The whole section of rendering plant my be divided into edible fat section and inedible fat section.

Inedible area: All materials unfit for human consumption with exception of hides and skins should be kept in the section away from edible areas called inedible area.

Equipment wash: An equipment wash section must be designed to avoid buggies, bins and washing of equipment at improper places. The one-way system of passing in equipment, wash section ensures the entry of dirty equipment's entry from one side and exit of only clean equipment's from other side.

Manure bay: A large amount of dung from lairage, emptying of rumen and intestine need a separate section to deal with this huge mass to avoid problem of flies etc. Floors and walls of this area should be impervious, easily washable, properly drained and can be easily disinfected. The floor should be at lower level than other floors in the slaughter-house.

Veterinary office and laboratory: This section should have essential facilities and equipment's to carry out inspection work.

Vehicle washing: There should be separate sections for cleaning of meat transport and animal transport vehicles.

Facilities for personnel: The abattoir building should have well located toilet rooms Sufficiently away from slaughter walls, separate hall with lockers and shower facilities, changing room, adequate facilities for drinking water, washing, canteen and first aid at convenient location, parking areas and security arrangements etc. as per number of staffs. We will read these facilities in detail in the next unit.

Effluent treatment plant: This is the section, which deals with treatment of waste before their safe disposal in environment. We will read this effluent treatment else where in this chapter.

|

| Layout of Modem Abattoir Meat Plan |