During construction of an abattoir/meat plant following points should be considered:

Premises: It is required to be approved and registered by local authorities. While submitting plans for an abattoir, it is usual to submit two sets of drawings and four sets of specification to the responsible authority for approval. The plans include site plan, floor plan and plumbing plan. The site plan must show complete premises and the location in relation to roads, railways, waterways, adjoining properties and their function, catch basins, water and sewer lines, storage tanks etc. The floor plan must explain layout of walls, doorways, windows, partitions, rail system, equipment benches, platforms, toilets, chutes, conveyors, stair cases, hot and cold water connections, ventilation, fans, work positions of operatives, position of drainage gutters and floor gradients etc. The details of drainage system should be in plumbing plan. The plant building floors, walls, ceiling, partitions, doors and all other parts of the structures shall be of such material, construction and finish that they can be readily and thoroughly cleaned.

Roofing: It provides framework of the roof of wood or steel. The roof may be made of corrugated aluminum, asbestos or iron. Galvanized steel plates for the bottom of the doors are used on the outside for protection against rodents.

Construction material: The general principle regarding the choice of materials for constructing slaughterhouse is that the materials must be durable and be able to resist deterioration or destruction from external influences such as the weather. The materials must be impervious to water and blood and not stained by fat. We must consider the use of local materials for building abattoir to minimize the construction cost.

Coves: It provides rounded corner for sanitation at the juncture of walls and floor.

Floor: It should be impervious, non-absorbent, non-slippery and should have suitable gradient for drainage's. To make the non-slippery surface carborundum or aluminum oxide is incorporated.

Interior walls: The walls required to be smooth, flat and constructed of glazed, bricks/tiles or other non-toxic and non-absorbent, durable, light colored material. There should be a washable finish up to height of not less then 3 m from the floor. Wall sheets are often used in the form of plastic laminates, aluminum, polished asbestos, stainless steel or PVC-faced metal free from rust.

Ceilings: It should be of good height, minimum 5 m, smooth and flat, cement plastered, water resistant and impervious to minimize condensation, mould development and easy to clean.

Window ledges: It should slope at 45C to promote sanitation. Window sills should be 1200mm above floor level. There should be mechanical venting in roof structure.

Doorways and doors: It should be at least 2.5 m high, 1.5 m wide and made up of rust resistant metal.

Pest control: The ingress of rats, mice and insects can lead to serious problems as they are carrier of a number of zoonotic diseases. Insect and rodent screens should be provided in abattoir. There should be air curtain at reception, despatch, landing and off loading platform.

Anteroom: There should be an anteroom at main entrance where the air curtain exists.

Vehicular areas: Properly drained and concrete paved areas extended at least 6 m from building or livestock platforms should be provided at places where vehicles are loaded or unloaded. Pressure washing jets and disinfection facilities should be provided for tracks carrying animals.

Drainage: There should be efficient drainage system. All washing's or wet cleaning must course over the slaughter floor into a collecting drainage and empty eventually outside the building. As a general rule, one drainage inlet should be provided for each 37m^2 of floor space and a slope of 20 mm per meter to drainage inlets should be there for usual condition. Suitable removable metal screw plugs should be provided in the floor drains. Floor drains should not be provided in freezer room and dry storage room. Each floor drain should be equipped with a deep seal trap and drainage line should properly be vented to the outside air. Drainage line for toilet, urinal should be separate and drainage systems should discharge into a septic tank. Floor drainage valleys are essential under the dressing rails and such valleys should be 600 mm wide and should slope at 10 mm per meter to drains with the valleys.

Light and ventilation: Abattoir should be constructed in such a way that adequate natural light and ventilation is available. For natural light windows should face to north with provision for glass. Uncolored glass may be used in skylights and windows. The glass area should be approximately one-fourth the floor area of a workroom. Artificial light and ventilation should be provided alternately by mechanical means. The type of lighting must not distort colors. It is generally recommended that the overall intensity of light should not be less then 540 lux (50 ft candles) at all inspection points, 220 lux (20 ft candles) in work rooms and 110 lux (10 ft candles) in other areas. The intensities of light are usually taken at levels of 0.9 m from the floor, except in inspection areas where the height is 1.5 m. Ventilation is necessary to overcome excess heat, steam, condensation, odour, dust accumulation etc. There should be sufficient and suitable means for ventilation to the outside air. Care should be taken that in no case the dressed carcasses are exposed to direct sunlight.

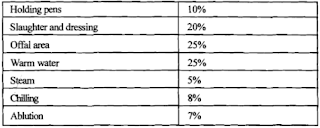

|

| Average water consumption in an abattoir |

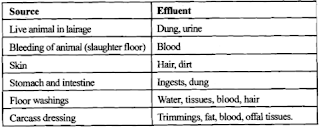

Disposal of abattoir effluent: The volume of waste water from abattoir is 80-85% of the water intake. This waste water typically contains the following contaminated waste material: blood, bits of meat, fat, paunch contents, urine and dung. Each of these waste materials contributes to a high organic load as well as considerable amount of suspended material in the waste water.

The disposal of organic waste from slaughterhouse and the effluent treatment will be discussed in course BPVI.

|

| source of effluent in an abattoir |

Many construction tools, from claw hammers to scaffolding through saws and hammers, do a specific purpose and require care and attention to use safely. Here are some suggestions for reducing your risk when using tools on the job and keeping you safe and alive while getting the task completed fast.

ReplyDeletehttps://www.maymaar.pk/

Thanks for sharing this blog post. We, Pearl Bath is leading Floor Drain Suppliers from Delhi India.

ReplyDelete